In the fast-paced world of fashion, collaboration is key.

Design teams need to work in sync to keep up with the ever-changing trends and consumer demands.

However, maintaining this synchronization is undoubtably a challenge.

From managing complex design processes to ensuring consistency across global teams, the hurdles are many.

But, with the right tools, these challenges can be overcome.

In this guide, we'll explore the best fashion design collaboration tools that can streamline your operations, foster creativity, and improve efficiency. Whether you're an operations manager or a fashion product development specialist, you'll find practical solutions to enhance your team's productivity and keep them in sync.

The Importance of Effective Collaboration in Fashion Design

With multiple stakeholders involved - from designers and manufacturers to marketers and retailers - clear communication and seamless coordination are crucial for success.

However, achieving this level of collaboration used to be easier said than done, now there are a plethora of software tools that aid fashion brands in their collaboration together.

Fashion design teams face numerous challenges, from managing complex design processes to coordinating with their global partners around the worldd.

Miscommunication leads to costly errors, while inefficiencies oftentimes delay product launches.

Moreover, the fast-paced nature of the fashion industry demands quick decision-making and rapid response to changing trends, adding another layer of complexity to the collaboration process.

Key Fashion Design Collaboration Tools

To overcome these challenges, many fashion design teams are turning to collaboration tools. These tools are designed to streamline workflows, improve communication, and foster creativity.

They come in various forms, each with very unique features and benefits. Let's take a closer look at some of the key tools in the market in 2024 and most likely, beyond:

1. Tech Pack Creators

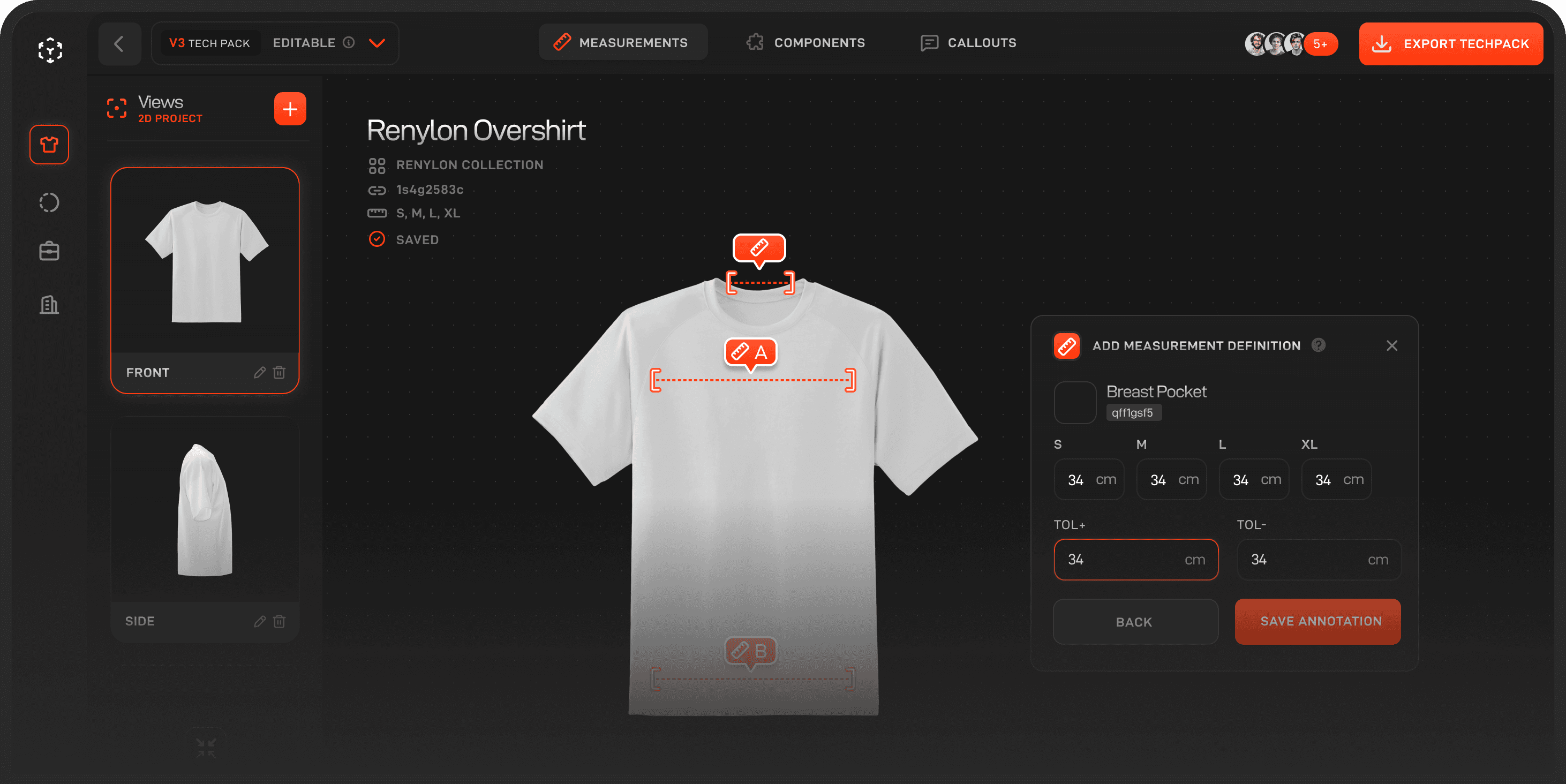

Tech pack creator software is a game-changer in the fashion industry. Fashion tech packs help designers create detailed tech packs that manufacturers can easily understand. These tools ensure that all design specifications are accurately communicated, reducing the risk of errors and misunderstandings.

Not only this, but they also save designers multiple hours per week due to the speed of using these tools.

The latest in tech pack creation software not only allows for version control, helping you keep track of what has changed, but also previews of 3D models of apparel.

Tech Packs traditionally have been shared as PDFs, but now that is changing. Static documents often become confusing with their many versions as changes are made. Tech pack software such as the one provided by Lifecycle allows you to share PIN-protected tech pack URLs, that update as you update your tech pack.

2. Fashion Design Software

Fashion design software simplifies the design process. It allows designers to create and modify designs digitally, eliminating the need for manual sketches.

This not only speeds up the design process but also makes it easier to share and collaborate on designs. A popular fashion design tool is Clo3D, allowing fashion designers to create 3D renders and drape fabric on mannequins to assess how the garment will look.

The level of detail in these 3D renders ensures less miscommunication during sampling.

A great PLM software will have support for these models so that they can easily be transformed into tech packs. Others may also have support for Adobe Illustrator too, so traditional 2D sketches can be synced easily.

3. Fashion PLM Systems

Fashion Product Lifecycle Management (PLM) systems are crucial for managing the entire lifecycle of a fashion product. They help teams track and manage all aspects of product development, from initial concept to final production.

By centralizing all product-related information, these systems enhance transparency and collaboration across the team. The idea of having all information centralized, is often the most powerful but strangely overlooked aspect of PLM software.

Most fashion teams cannot scale beyond a certain point due to disjointed information and processes, and PLMs solve this issue – amongst many others.

PLMs have often only been available for huge enterprise fashion brands, due to their cost – but that landscape is starting to change, as companies such as Lifecycle look to provide for the hundreds of thousands of fashion brands that are looking to be more organized and efficient.

4. Cloud-Based Fashion Chat Tools

Cloud-based fashion collaboration tools enable real-time collaboration. They allow team members to access and update team members on designs from anywhere, at any time.

This is particularly useful for teams spread across different locations or working remotely. Lifecycle includes a team Console, that allows teams to chat together regarding different products, orders, and shipments – even enabling them to assign tasks to each other and have visibility on all updates across the software.

This visibility and communication enhancement allows teams to get things done together, faster.

5. Fashion Sampling and Virtual Prototyping Tools

Fashion sampling tools allow designers to create virtual prototypes. This not only speeds up the sampling process but also reduces the need for physical samples, saving both time and resources.

These tools also make it easier to share and review samples, facilitating faster feedback and revisions. Tools like Lifecycle allow teams to quickly upload photos of samples, annotate them, do QC fit checks and send the feedback straight back to the manufacturer via a secure URL link – saving teams time, and money on their bottom line.

Implementing Collaboration Tools in Your Workflow

Once you've chosen the right collaboration tools for your team, the next step is implementation. This involves integrating the tools into your existing workflow and ensuring everyone knows how to use them.

Remember, the goal is to streamline processes, not complicate them. So, it's crucial to choose tools that fit seamlessly into your workflow and enhance your team's productivity – or that have easy to use user interfaces, that don't take a long time to learn.

Integration with Existing Systems

A key aspect of implementation is integration with existing systems. Your new tools should work well with the software and systems your team is already using.

This might involve integrating your fashion design software with your PLM system, or syncing your tech pack creator with your Adobe Illustrator suite. Seamless integration ensures a smooth workflow and reduces the risk of data silos.

Ultimately, moving to a tool like Lifecycle where most tools can even be replaced, is good for fashion brands the long run. Slack, email, Excel spreadsheets, PM tools like Asana, Jira, Trello, can all be replaced by Lifecycle – so integrations over time, become less necessary.

Training and Support

Training can be another crucial aspect of implementation. Your team needs to understand how to use the new tools effectively.

This might involve formal training sessions, online tutorials, or hands-on practice. Remember, the more comfortable your team is with the tools, the more likely they are to use them effectively.

In the past, many of these software tools were too complex for teams to onboard themselves, slowing the uptake of the product.

Now, with improvements in User Experience and easy-to-use interfaces, this is becoming less of an issue as the industry evolves – allowing brands to use software easily without assistance, or at worst, with the help of online tutorials and guidebooks.

Data Security and Intellectual Property

Finally, when implementing new collaboration tools, it's essential to consider data security and intellectual property. Your designs are valuable assets, and you need to ensure they're protected.

Choose tools with robust security features, such as encryption and access controls. Also, consider how the tools handle intellectual property rights to ensure your designs remain your property.

Tools such as Lifecycle make their tech packs sharable, but also PIN-protected so that only people holding the PIN can access it. These PINs can be refreshed at any time too, enhancing the security of valuable pre-production information, which, if leaked into the wrong hands could have competitors snooping.

Measuring the Impact of Collaboration Tools

Once you've implemented your new collaboration tools, it's important to measure their impact. This will help you understand whether they're delivering the expected benefits and where improvements might be needed.

You can measure the impact in several ways, including time-to-market, productivity, and the use of analytics and reporting features.

Time-to-Market and Productivity

One of the key benefits of collaboration tools is that they can reduce your time-to-market. By streamlining processes and improving communication, you can get your designs from concept to production much faster.

You should also see an improvement in productivity. With better collaboration and more efficient processes, your team should be able to get more done in less time, whether this is through faster sampling, better communication, or just having all information in one centralized place.

Analytics and Reporting

Many collaboration tools come with built-in analytics and reporting features. These can provide valuable insights into your team's performance and the efficiency of your processes.

For example, you might track how long it takes to complete a design, or how many revisions are needed. This data can help you identify bottlenecks and areas for improvement.

Conclusion

In conclusion, the right collaboration tools can transform your fashion design process. They can streamline workflows, foster creativity, and drive innovation. But more than that, they can help to create a culture of efficiency and collaboration within your team. Adopting these tools is not just about keeping up with the latest trends. It's about embracing a new way of working that is more sustainable, more efficient, and more in tune with the fast-paced world of fashion. So why wait? Start exploring these tools today and see the difference they can make in your fashion design process with Lifecycle.Lorem ipsum

Sam Lillicrap

CEO OF LIFECYCLE FASHION PLM

Continue Reading