The fashion industry is experiencing a profound transformation as it shifts from mass production to more customized, consumer-centric approaches. This evolution is driven by technological advancements and changing consumer preferences that prioritize individuality and sustainability. At the heart of this transformation is Product Lifecycle Management (PLM) software, which equips fashion brands with the capabilities to personalize and streamline their design and production processes, enabling them to cater to specific consumer needs while maintaining efficiency and quality.

The Move Towards Customization

In the past, fashion was characterized by mass production, where uniform products were manufactured at scale to meet global demand. Today, however, consumers crave unique, personalized items that reflect their personal style and values. This shift has made customization a key differentiator in the fashion industry, offering several benefits:

Increased Consumer Engagement: Personalized products foster a deeper connection with consumers, enhancing brand loyalty and satisfaction.

Reduced Waste: Producing items based on specific consumer orders minimizes overproduction and excess inventory, aligning with sustainability goals.

Stronger Brand Differentiation: Customization allows brands to stand out in a crowded market by offering unique, tailored experiences.

How PLM Enables Customization

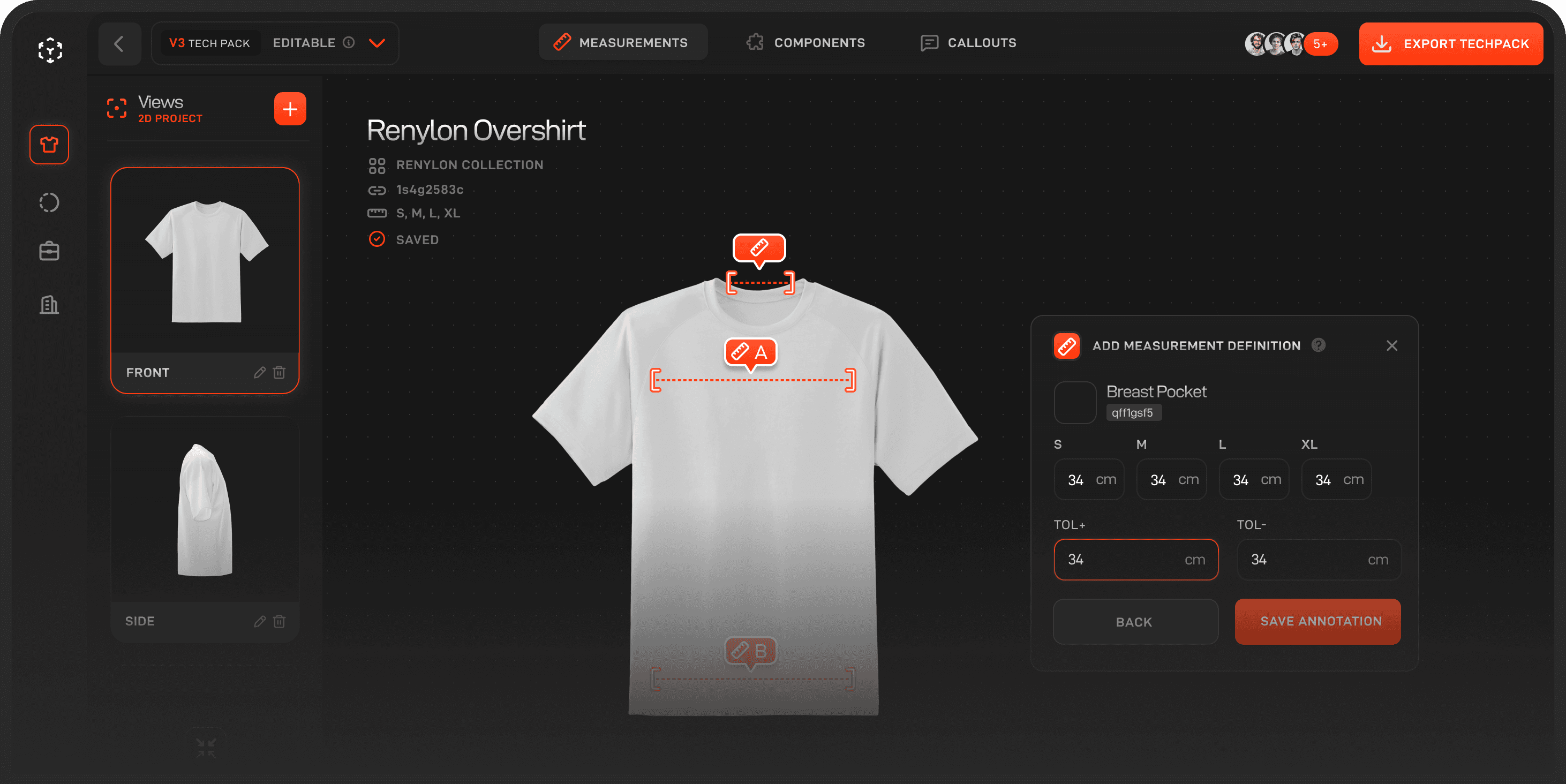

Comprehensive Data Management: PLM systems centralize product data, allowing brands to manage detailed specifications and consumer preferences efficiently. This capability is crucial for customizing products to meet individual customer requirements.

Streamlined Workflow: By automating the design and approval processes, PLM reduces the time and complexity involved in developing customized products. The software ensures that all changes are documented and accessible, facilitating smooth collaboration across teams.

Flexible Supply Chain Integration: PLM enhances supply chain coordination by integrating data from design, sourcing, and manufacturing. This synchronization ensures that customized products are produced efficiently, maintaining quality and minimizing lead times.

Advanced Design Tools: PLM systems offer advanced design tools that enable designers to experiment with different materials, colors, and styles in a virtual environment before finalizing a customized product. This feature supports creativity and innovation while minimizing costly prototypes.

Real-Time Consumer Interaction: PLM enables brands to capture and analyze consumer data in real-time, allowing for immediate adjustments based on consumer feedback. This responsiveness ensures that customized offerings meet consumer expectations and market trends.

The Future of Fashion Customization with PLM

As PLM technology continues to evolve, it will incorporate even more sophisticated tools for customization, such as AI-driven analytics for trend prediction and machine learning for design optimization. Additionally, the integration of Augmented Reality (AR) and Virtual Reality (VR) within PLM will offer consumers immersive, interactive experiences in designing their own garments.

Conclusion

The shift from mass production to customization represents a significant evolution in the fashion industry, driven by consumer demands for personalization and sustainability. PLM software is pivotal in this transformation, providing the framework and tools needed to deliver customized products efficiently and effectively. For fashion brands, embracing PLM-driven customization is not merely a trend but a strategic imperative to remain competitive and relevant. By harnessing the power of PLM, brands can unlock new opportunities for innovation, customer engagement, and market differentiation, ensuring they lead in a rapidly changing fashion landscape. This commitment to customization heralds a future where individuality and creativity take center stage, aligning brand values with consumer expectations and environmental stewardship.

Sam Lillicrap

CEO OF LIFECYCLE FASHION PLM

Continue Reading